Welcome to Enhanced Manufacturing Solutions, Inc.

Site is in rebuilding currently

About Us

Enhanced Manufacturing Solutions is an exclusive representative of Mayfran International in Southwest Ohio and the entire state of Kentucky.

MAYFRAN INTERNATIONAL CORPORATION

Enhanced Manufacturing Solutions is a representative of Mayfran International in Southwest Ohio and the entire state of Kentucky.

Mayfran is a global leader in providing engineered solutions for scrap and coolant management and material handling in metalworking, recycling, solid waste processing, and other applications. Mayfran’s products convey, filter, separate, shred, briquette and process materials and fluids for the automotive, aerospace, consumer products, oil and gas, steel processing, solid waste, pulp and paper, medical products, heavy equipment and related industries. Mayfran’s engineered solutions promote sustainable manufacturing processes, reducing costs while improving overall profitability and competitiveness. There are significant benefits to working with Mayfran on your chip, coolant, and scrap management projects.

Mayfran was established in 1933, is headquartered in Cleveland, Ohio, USA, and has operations around the world.

Mayfran products

Machine Tool Chip and Coolant Solutions

Machine Tool Chip and Coolant Solutions

With an industry-leading array of chip and coolant management solutions for your machine tool, Mayfran offers systems that meet nearly any machining challenge. Our relationship with most major machine tool producers provides access to machine designs and an ability to quickly provide a tailored solution fit to your needs. Mayfran offers systems for both new equipment and aftermarket replacements and upgrades.

Coolant Filtration Systems / Chip Processing

TD-Series Pneumatic Discharge wringers, an ideal solution for lighter materials like aluminum, and capable of processing steel, brass, and stainless steel

VBU-Series (Vertical Bowl Up) wringers

The low cost VBU Series Wringer from Mayfran is ideal for medium chip volumes. It offers a solution to handling wet chips in today's machine shops.

Dried chips can be safely stored and transported. It also allows the reclaiming of coolant for recycling.

ArmorLift® LBC (Lift Bottom Centrifuge) wringers

The lift bottom centrifuge is designed for continuous operations. This up and down motion of the live bottom pushes the chips upward through the sieve. The centrifugal force, up to 500 times the force of gravity, will dry the chips, resulting in the maximum degree of de-oiling. The remaining oil content is extremely low. The dry chips fall down over the edge of the drum into a container. The are different models and different drives available.

Material and Scrap Handling / Recycling

The innovative shuffle-drive system leads the way in providing solutions for scrap management at the press, yielding improvements in press availability and throughput with reduced operating costs. With systems typically yielding a payback on your investment in less than a year, you can quickly enhance your competitiveness in the challenging metalforming market.

· High reliability practically eliminates downtime for maintenance and repair

· Easy tray attachment speeds die changeovers

· Electric operation saves utility costs vs. air shakers

Stamping Scrap Systems

With a range of options available, Mayfran can complete your scrap collection system with automated loadout into rolloffs, balers, bins, or trailers. Loadout systems include swivel chutes, diverter chutes, orshuttle conveyors, all of which can include laser sensors and automated feedback to provide level filling and communicate status automatically to central control systems. Direct notification to scrap haulers is also possible, truly minimizing your effort in managing your scrap system.

Mayfran scrap loadout systems are designed to the same exacting standards as our conveyors, enabling you to keep production running on even the most demanding schedules.

new products

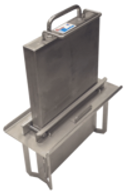

manual sludge barrier

The Sludge Barrier is a compact and portable magnetic separation system that removes small ferrous chips and fines from the coolant tank preventing in-tank sludge build-up while simplifying recovery and disposal for ease of maintenance. The Sludge Barrier is ideal for steel, cast and/or ductile iron applications.

- Easy retrofitting to any coolant tank

- Mount near the pumps to reduce the amount of particulate sent back to the machine

- Mount next to the conveyor to remove ferrous particles as they exit the conveyor

Auto-Sludge Barrier

The Auto Sludge Barrier is a motorized automatic magnetic separation system that removes small ferrous chips and fines from the coolant tank preventing in-tank sludge build-up while simplifying recovery and disposal without troublesome manual operations. The Auto Sludge Barrier is ideal for steel, cast and/or ductile iron applications.

- Easy retrofitting to any coolant tank

- Stainless steel construction for functionality and durability

- 110 Volt version is designed to work with a standard 110V receptacle

- Repeat cycle timer for flexibility to handle larger chip loads while reducing coolant carryout

- Mount near the pumps to reduce the amount of particulate sent back to the machine

- Mount next to the conveyor to remove ferrous particles as they exit the conveyor

- Will also remove tramp oils, the number one contaminant of machine tool coolant systems

Contact Us

Drop us a line!

Enhanced Manufacturing Solutions, Inc

23 Hillcrest Estates Dr Batesville, IN 47006 US

Main (812) 932-1101 - Mobile (513) 240-1366

Copyright © 2019 Enhanced Manufacturing Solutions, Inc - All Rights Reserved.

Powered by GoDaddy Website Builder